The Greatest Guide To Highland Manor Wood Products, Llc

The Greatest Guide To Highland Manor Wood Products, Llc

Blog Article

Highland Manor Wood Products, Llc for Dummies

Table of ContentsThe Only Guide for Highland Manor Wood Products, LlcHighland Manor Wood Products, Llc Can Be Fun For EveryoneOur Highland Manor Wood Products, Llc StatementsThe Best Strategy To Use For Highland Manor Wood Products, LlcFascination About Highland Manor Wood Products, Llc

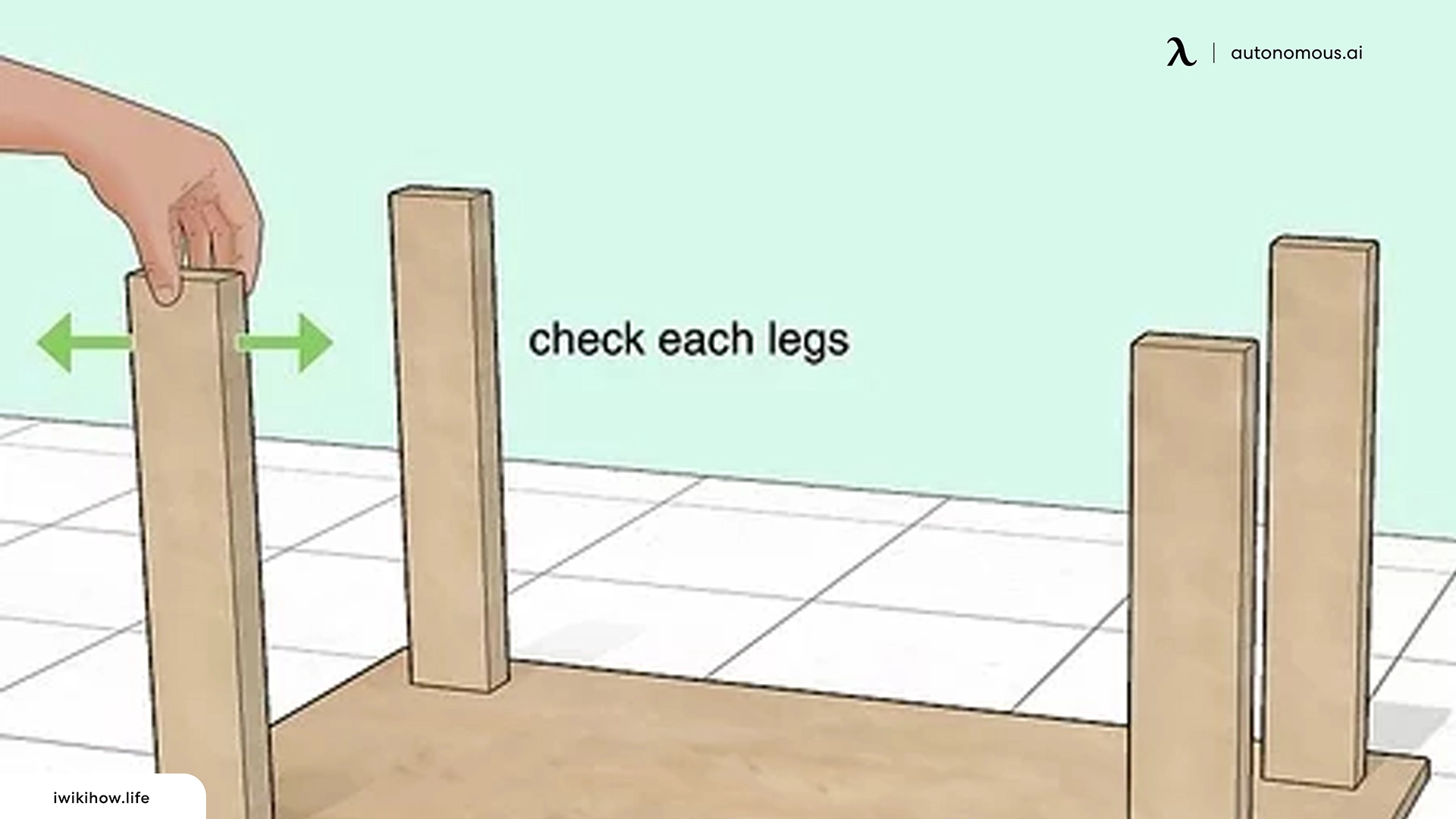

Clean the damaged edges of the table leg to guarantee a smooth, strong bond. Thoroughly line up the damaged pieces. Use clamps to hold the pieces together briefly.In addition, getting rid of the legs reduces the stress they may sustain if the table is lugged or filled incorrectly, avoiding them from birthing extreme weight or experiencing unnecessary pressure. Make certain that the table, specifically its legs, is firmly put in the moving vehicle. The table should not totter or have the potential to tip over.

All About Highland Manor Wood Products, Llc

Take the masking tape and cover your drill little bit regarding inches of the method down the bit. This is to help make certain you don't drill with the table top while ensuring the depth you need for the screws. Meticulously drill each of the screw openings to the proper depth, making use of the marks you made.

Use the influence chauffeur to screw each leg securely right into location. It's best to go one leg at a time to ensure the positioning is right and each leg is secure before moving on to the following.

(https://highland-manor-wood-products-llc.webflow.io/)

Repeat these actions to deal with any type of other damaged legs on the table.

Utilize a jig attended reduce them diagonally from edge to collar to produce 4 edge blocks. Cut a notch out of the rear of the edge block opposite from the diagonal cut to ensure that the notch fits over the top of the leg and provides additional toughness in the edge.

6 Simple Techniques For Highland Manor Wood Products, Llc

Drive one even more screw, focused with the block, right into the corner of the table leg. Increase your lightweight table by including some ballast. This serves to flatten wayward, thin table tops, in addition to add some weight to keep them where they belong. Procedure the size and width under the table in between the legs.

Whole lots of tables have built-in stretchers to add stability. 2 stretchers run in between the sides of the legs on the table's short ends, with one long stretcher connecting the 2 brief stretchers in the.

The 8-Second Trick For Highland Manor Wood Products, Llc

Each piece has its own story to inform, and antique table legs play an important function in the general appearances and security of these prizes. Recovering them not just revives their elegance however additionally aids maintain their historical value. Recognizing antique table legs begins with acknowledging the different kinds of antique tables and their historical contexts.

Antique tables come in various styles, such as Queen Anne, Chippendale, or Victorian, each with its distinct layout and attributes. Recognizing the type of table you have will certainly guide your remediation initiatives.

French bnisterie furnishings, with its detailed workmanship, would likely be most worth bring back and might necessitate specialist services, whereas a table discovered at a yard sales may not validate the remediation cost. As you start the trip of recovering antique table legs, among the initial and pivotal actions is to closely check out these important components of your valued item.

The Highland Manor Wood Products, Llc Statements

Begin by looking at the surface area of the table legs carefully. Try to find any visible splits that may have developed in time. Splits can vary in size and severity, from minor surface area blemishes to deep structural fractures. Each split tells a tale of the table's history, and addressing them is essential for both aesthetic appeals and structural stability (wood Corner Guards).

These splits can compromise the general stamina and appearance of the legs. Recognizing their visibility and degree is important before proceeding with reconstruction. Butt joints are more vulnerable to splitting because they provide a limited surface for glue bonding, making them susceptible to separation under stress or stress. Pay very close attention to the joints where the table legs fulfill the table's structure or apron.

Review the total structural stability of the legs. By meticulously analyzing the wear and damage, you can develop a comprehensive repair plan customized to the certain requirements of your antique table legs.

Report this page